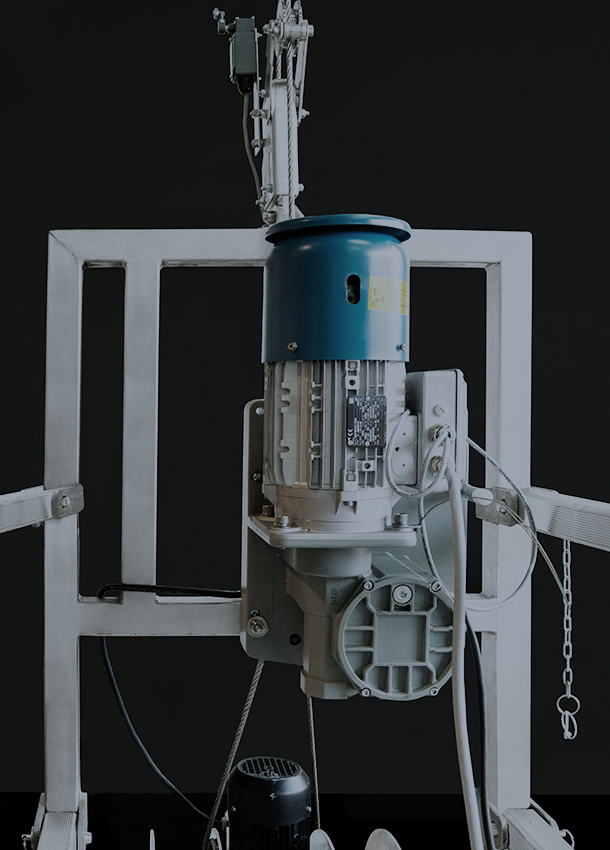

A compact lightweight hoist

Traction hoist for man-riding and materials handling

THE UNILIFT SERIES traction hoists is designed for lifting and lowering people or material without height limits. Capacities range from 500kg to 2000kg at either 9 or 18 m/min.

The power hoists have flexible attachment points, manual safety lowering mechanism, embed overload mechanism and operanting hours counter. The rope is not connected which makes it compact, lightweight and very easy to handle.

The UNILIFT hoist is versatile and suitable for a large number of applications.

Designed and manufactured according to EN1808:2015 and certified by TUV Rheinland (recognized by OSHA)

The UNILIFT hoist is available in the following capacities:

- 2000 kg

- 1000 kg

- 800 kg

- 630 kg

- 500 kg

FBA gomyl has a maintenance center at its facilities in Barcelona where the hoists can be overhauled, inspected, repaired and maintained. We can also train people to perform proper hoist maintenance locally and how to install a hoist.

Applications

- Construction and industry

- "Scaffoldless installation process" in the today's elevator installation methods that focus on safety and efficiency

- Windmill applications

- Temporay and permanent suspended plataforms

- Material lifting

- Special applications requiring man-riding

Advantages

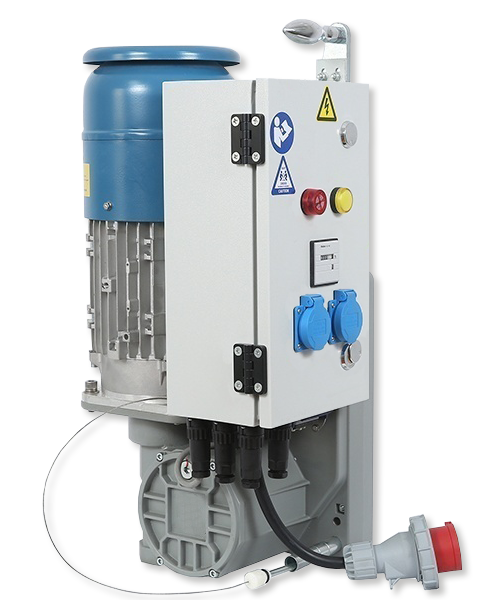

- Structure design in die-cast aluminium

- Built-in Overload Mechanism

- Safety Lowering Mechanism

- Hour counter

- Flexible Attachement Points

- Gearing and drive sheave is fabricated from hardened steel

- Drive sheave and pressure rollers of special nitrided steel

- Standardized components ensures easy access to all wearing parts

- Universal attachments

- Motor protection IP55 as standard

- Motor thermal protection device

- Electrical phase monitoring

Working at height legislation

EN1808:2015 and certified by TUV Rheinland

UNILIFT traction hoist for the elevator installation process

Developed for a wide range of man-riding and material lifting applications.

In elevator installations where safety and efficiency are crussial, a wire rope traction hoist is used to lift platforms or cabins during the installation of various elements of the elevator cage.

The UNILIFT hoist, equipped with a range of accessories, can be adapted to any elevator installation procedure and helps elevator companies to work faster, more efficient, safer for a lower price.

Our engineering department supports the elevator company in the design of the installation process to find the solution that best fits their products and methods for the lift installation and maintenance.

Accessories:

- Pulleys of 2T or 4T to work with double capacity

- Adapters for the connection of the hoist to anchor points on the ceiling or in the platform

- Overspeed fall arest devices

- Limit switch to automatically stop the movement of the hoist

- Rope guide spring to deviate the cable when it is attached to the ceiling

- Running hours counter for letting know when the next maintenance must be performed

UNILIFT traction hoist for temporary or permanent suspended platforms

According to the EN1808:2015, hoisting systems in suspended access platforms must comply with a number of different characteristics for working at heights in a safe way. For this reason, the UNILIFT hoist is equipped with safety systems for fall protection, such as:

- An overload sensor to prevent lifting more than the maximum capacity

- A manual lowering mechanism to allow the platform to be descended manually and safely in the event of a power failure.

- Dual brakes: electromechanical motor brake and centrifugal brake as backup

- Safety triggers coupled to the hoist in an independent wire rope to avoid a free-fall in any case: overspeed safety trigger or a slack wire rope detector.

In addition to the safety measures, the UNILIFT has:

- An IP55 protection rating making it suitable for use in difficult and hazardous environments and able to operate at temperatures between -20°C and 55°C

- A solid and lightweight housing made of die-cast aluminium

- A phase control system and thermal overload protection

- Can be supplied with a pendant or remote control

The hoist machine can be used as a material hoist. This option should be studied by our engineering department for specific projects taking into account various aspects such as the material hoist capacity, safety, configuration and installation.

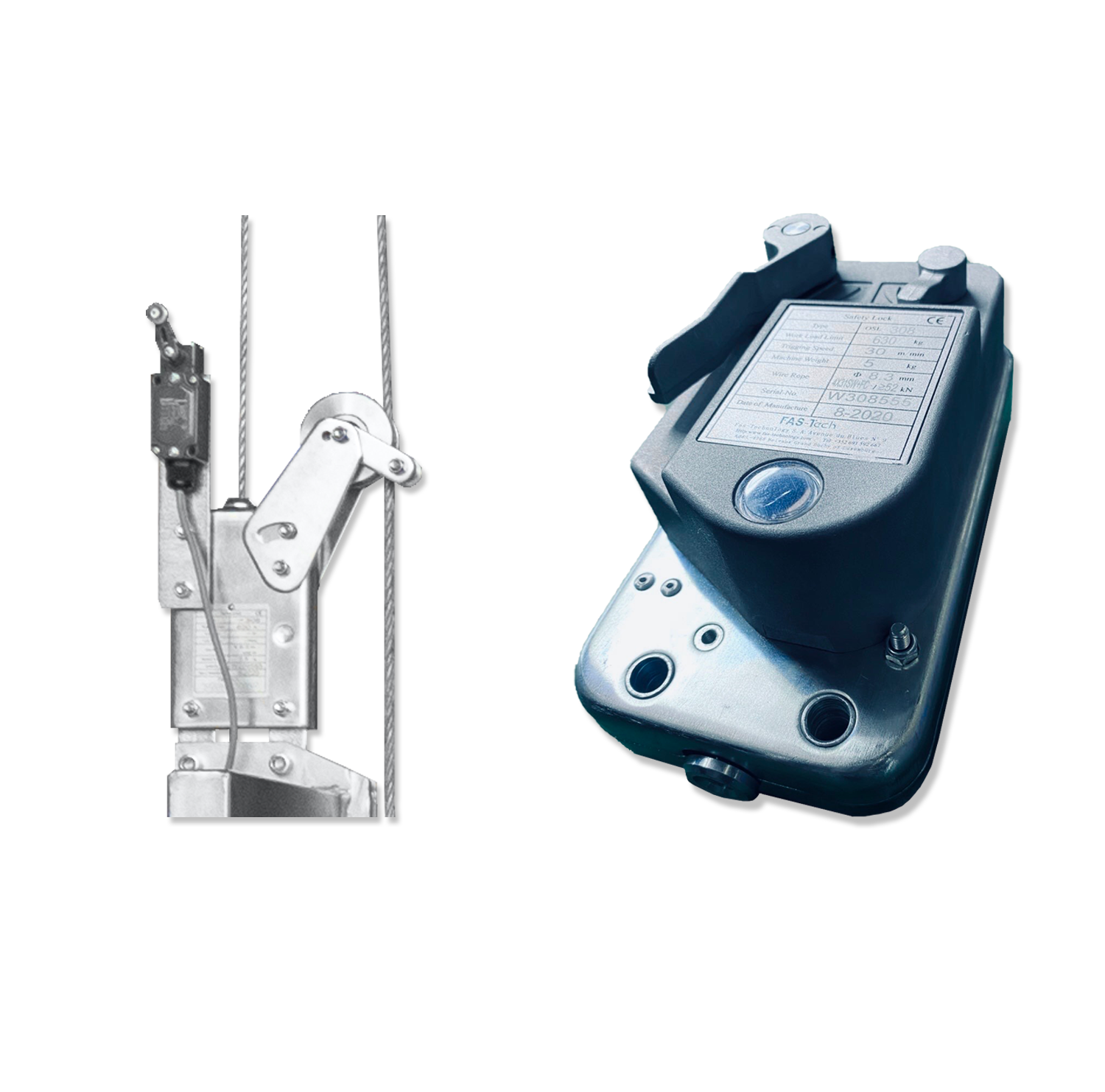

Anti-tilting wire rope safety device (LSF) & Overspeed wire rope safety device (OSL)

The anti-tilting fall arrester is automatically triggered when the angle of the rope or platform exceeds a certain angle.

The integrated clamping jaw mechanism holds the rope firmly and immediately stops the movement of the system.

The overspeed safety device is automatically activated when the lowering speed on the cable exceeds 30m/min (0,5m/s).

The special integrated clamping jaw mechanism made of hardened special steel immediately blocks the suspended load on the wire rope.